Track Systems creates application-specific designs for flow racking to accommodate storage and line-side requirements. Our flow rack systems feature:

- Tool-less or bolted construction

- Variable load capacity

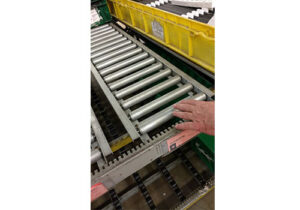

- Multiple roller selection

- Modular Flow Rack structures

- Caster and accessory alternatives

- Vertical and horizontal shelf adjustments

Our flow rack adjusts to fit the job. With our products you can:

- Change the height

- Adjust the tilt

- Shift the rollers to fit different bin sizes

- Remove the shelves as needed

With mobile flow racks from Track Systems, production work cells can have an uninterrupted supply of parts, speeding up the assembly process.

Each rack comes with adjustable-angle shelves, each with adjustable heavy-duty conveyor rollers. The shelves slope or tilt to allow containers to flow from load end to picking end. This position allows the shelf components to be closer to workers, helping reduce repetitive motion injuries.

Why Choose Track Systems Custom Flow Rack Systems?Introducing LineFlow

By minimizing bending and reducing undue stress on the back and limbs, LineFlow™ flow rack from Track Systems satisfies the ergonomic requirements of your operators while at the same time increasing productivity. The patented LineFlow™ adjustment feature allows universal drop-in tracks to be easily re-positioned by hand into beam slots spaced ½” apart. Unique “worker-friendly” features enable the operators to correctly position the first shelf between waist and shoulders, the second shelf between waist and knees, and the third shelf (return shelf with an opposite slope for empty containers) at the knee level. Horizontal and vertical shelf adjustments are performed in minutes and can be safely secured without tools. By merely relocating an adjustment block, the shelf assembly is adjusted to the desired location.

Locking casters provide simplified cleaning of work stations and allow immediate relocation to serve alternative line applications. LineFlow™ wheeled tracks will handle almost any carton, tote, or custom container conveying loads of up to 10,000 lbs per shelf.

What Are Flow Racks?

Flow rack systems are shelving units designed to feed product according to your unique needs to maximize efficiency.

Flow rack systems are an excellent addition to your warehouse to help increase efficiency and maximize profitability. Designed to efficiently feed product when and where you need it, these shelving units feature rollers, wheels, or rails, that allow your products to easily glide to where you need them most. Flow rack systems can be tilted or flat, to allow for manually fed, or gravity fed product movement. Depending on need and workflow placement flow racks can be utilized in both LIFO & FIFO inventory systems. Our custom flow rack solutions can be designed to move a variety of materials from bins and boxes to individual parts.

Flow Rack Advantages

Implementing LineFlow flow racks in your warehouse has several benefits, including:

Better Inventory Management

- By controlling material flow and putting the right product in the right space at the right time you can help promote proper inventory rotation and track inventory levels with ease

Safer and Healthier Work Environment

- By minimizing bending and reducing undue stress on the back and limbs, LineFlow™ satisfies the ergonomic requirements of your operators while at the same time increasing productivity.

Maximum Mobility and Flexibility

- Locking casters provide simplified cleaning of work stations and allow immediate relocation to serve alternative line applications. LineFlow™ wheeled tracks will handle almost any carton, tote, or custom container conveying loads of up to 10,000 lbs per shelf.

Increased Visibility

- By better utilizing your floor space with flow racks, you can have increased visibility, promoting safer and more productive employee behaviors.

Reduced Travel & Movement

- Strategically implemented flow rack solutions means less needless unproductive travel for your employees.

Short-Term Payback

- A safer work environment and a more productive workforce means greater output and reduced downtime – creating greater profitability for your business.

Where Are Flow Rack Systems Used?

Flow rack systems can be used in practically any space that would be aided by more efficient, versatile, and easier flow of materials. Flow racks can be used for extended storage of goods and/or temporary storage of goods in transition from storage to dispatch. Whether your inventory flow is LIFO or FIFO, flow racks will help create a more efficient flow of goods.

Types Of Flow Racks

There are many different types of flow rack to fit your unique needs, including:

Roller Rack

Skate Wheel Flow Rack

Flow Rail Gravity Rack

Modular and Mobile Flow Rack

Column Flow Gravity Rack

Tilt Shelving

Not sure which you need? Call Us!

We can help recommend the right flow rack system for your needs.

Custom Flow Racks

LineFlow Technical Information

Standard Completed Assembly Sizes

| Height | 54” and 72” |

| Width | 12”, 18”, 24”, 36”, 48” and 60” |

| Depth | 36”, 48”, 60”, 72”, 84” and 96” |

Standard Completed Assembly Sizes

| Upright Frames | 54” or 72” Height X 36”, 48”, 60”, 72”, or 84” Depth |

| Anti-Sway Bars | 12”, 18”, 24”, 36”, 48” and 60” Length |

| Cross Beams | 12”, 18”, 24”, 36”, 48” and 60” Length |

| Side Rails | 36”, 48”, 60”, 72”, 84” and 96” Length |

| Flanged Wheel and Flat Wheel Tracks | 36”, 48”, 60”, 72”, 84” and 96” Length |

| Finish | All metal surfaces are powdered coated to a nominal thickness of 1.5 mils. Standard colors are black, beige and gray |

OPTIONS

| Medium or Heavy-Duty Caster Kit | Two swivel with lock, two rigid |

| Pick Trays | 12”, 18”, 24”, 36”, 48” and 60” Length X 12” Width |

| Tool Holders | Right and left hand-mounted on upright key slots |

| Computer and Keyboard Support Stand | Sized as required |

| Special Paint Color | Powder coat and enamel |