Track Systems comes backed with 40 years of material handling and manufacturing experience and in-depth industry knowledge to provide one-stop solutions for our customers. Our carts, flow racks, tilts, lifts, trolleys, work stations and custom product solutions have all been evaluated for safety of operation, life cycle performance, and engineered for sustainability. Let us meet you where you are at with custom fabrication and consulting options or browse our products and see what we can help you achieve. All designs have been vetted via customer collaboration, application and human engineering, and cost-effective use of capital.

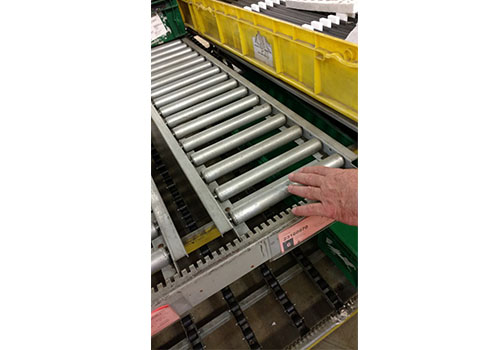

FLOW RACKS

Track Systems creates application-specific designs to accommodate storage and line-side requirements.

- Tool-less or bolted construction

- Variable load capacity

- Multiple roller selection

- Modular structures

- Caster and accessory alternatives

- Vertical and horizontal shelf adjustments

Our Flow Rack adjusts to fit the job. You can change the height, adjust the tilt, shift the rollers to fit different bin sizes, and remove the shelves as needed. With Mobile Flow Racks from Track Systems, production work cells can have an uninterrupted supply of parts, speeding up the assembly process. Each rack comes with adjustable-angle shelves, each with adjustable heavy-duty conveyor rollers. The shelves slope or tilt to allow containers to flow from load end to picking end. This position allows the shelf components to be closer to workers, helping reduce repetitive motion injuries.

By minimizing bending and reducing undue stress on the back and limbs, LineFlow™ satisfies the ergonomic requirements of your operators while at the same time increasing productivity. The patented LineFlow™ adjustment feature allows universal drop-in tracks to be easily re-positioned by hand into beam slots spaced ½” apart. Unique “worker-friendly” features enable the operators to correctly position the first shelf between waist and shoulders, the second shelf between waist and knees, and the third shelf (return shelf with an opposite slope for empty containers) at the knee level. Horizontal and vertical shelf adjustments are performed in minutes and can be safely secured without tools. By merely relocating an adjustment block, the shelf assembly is adjusted to the desired location.

Locking casters provide simplified cleaning of work stations and allow immediate relocation to serve alternative line applications. LineFlow™ wheeled tracks will handle almost any carton, tote, or custom container conveying loads of up to 10,000 lbs per shelf.

If you don’t see what you are searching for,

contact us and we’ll be happy to assist you with design, engineering and more.